Details

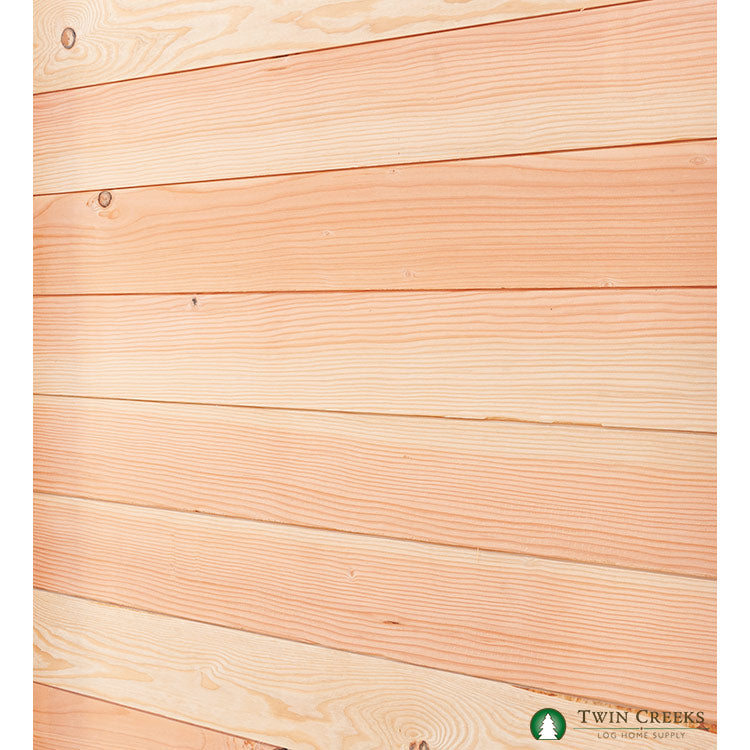

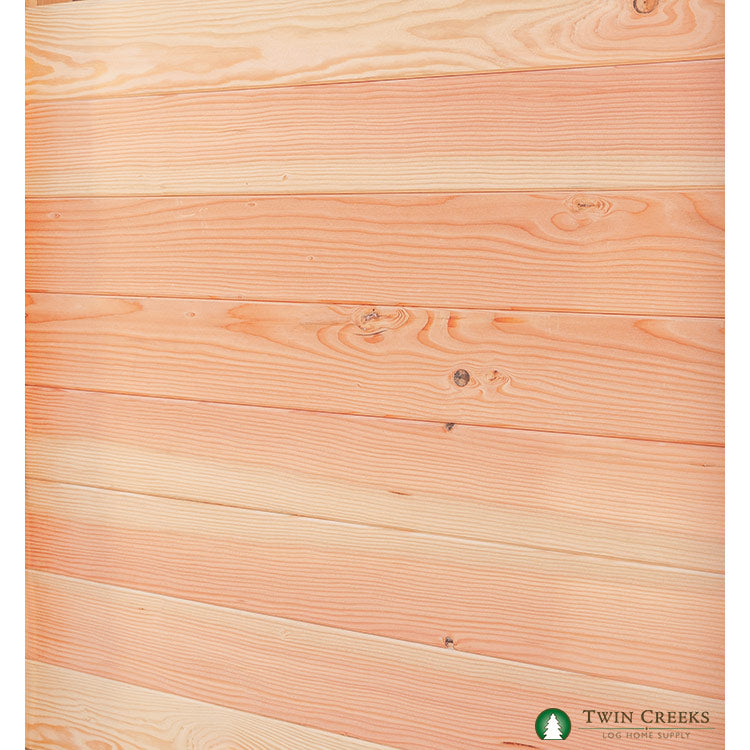

1x6 Douglas Fir Tongue and Groove Shiplap Siding

Also referred to as Nickel Gap, Square Edge Tongue and Groove, or Shadow Gap, the uniquely straight grain and reddish-orange color of Douglas Fir provides eye-catching appeal wherever it is installed. As one of the hardest and most dense of the softwood species, Douglas Fir makes a practical, as well as a beautiful, addition to your home. With a higher structural value over other softwoods, Douglas Fir is able to span further, making it perfect for those who need longer lengths for exposed beams, exterior siding, building frames, or flooring.

Product Highlights:

• Eye catching appeal

• Rich visual quality

• High structural value

• Dimensional stability

• Resistant to decay and insects

• Easily adaptable for any project

• Most sustainable and durable softwood

1x6 Douglas Fir Tongue and Groove Shiplap Siding Options:

• Typical Lead Time: Typically available in 1-2 weeks.

• Hewing Option: Hand Hewing is not available with this profile.

• Shipping Options: Flat-bed Tractor Trailer, Roll Back, and LTL Carrier; shipping method is based on location and order size to minimize cost.

• Details Disclaimer: While we strive to ensure product details are always accurate, product specifications may change and images shown may not represent current dimensions. Please call us if you would like to receive an up-to-date profile drawing.

Product Resources:

Douglas Fir Species Information

Tongue and Groove Roof Decking Installation Guide

Plank and Beam Framing Guide for Residential Buildings

Coverage Calculations:

You can calculate the coverage for tongue and groove using our Tips Page, How Do I Determine How Much Lumber I Need? Please call us if you would like a free takeoff on your project as well.

Preparation Information:

Our Kiln Dried 1x6 Douglas Fir Tongue and Groove Shiplap Siding is ready for installation once received on your jobsite. However, wood will shrink and swell with any changes in moisture content and weather. According to WWPA, to minimize dimensional change after installation, install tongue and groove at a moisture content that matches the local climate as closely as possible. If the climate in a particular region causes wood to maintain 8% to 13% moisture content annually, then the most ideal tongue and groove would be installed at a moisture content within that range, and the material would be stored, stickered and protected for a week to ten days prior to application.

Maintenance:

With any unfinished interior wood, applying a quality finish to all surfaces (including the ends) is recommended. An interior finish protects the wood from moisture absorption and UV degradation, and helps prevent any finger stains caused by touching the unfinished wood. On occasion, the shiplap siding may have a mill glaze that is produced when the material is manufactured through the planer. When mill glaze occurs, it is recommended to remove it by sanding prior to staining or clear-coating the wood. Sanding is not recommended as a first option unless every piece is sanded. We offer a wide selection of Water Based Interior Finishes that we can recommend based on the final sheen level and look that is desired. Most interior finishes do not have to be re-coated or reapplied depending on the UV exposure to your home. You can find all of the interior stains and finish products that we carry at our Interior Stains page.

Storage Prior To Application:

Prior to installation, shiplap siding needs protection from direct sunlight, water saturation, snow, ice, dirt, and other elements. Ideally, the shiplap siding should be stored in an enclosed building such as a garage prior to use. It is best to store the shiplap siding flat and off the ground with a vapor barrier so that moisture is not absorbed through the bottom boards of the stack. If stored outside, the siding should be protected with a waterproof covering elevated in the center so that water does not pool on the cover. We also recommend that you do not completely seal the bundle, as good air circulation is required to prevent any blue stain or molding.

Specifications

Reviews

Product Questions

| Features | |

|---|---|

Stack Height |

|

Available Lengths |

|

Grade |

|

Profile |

|

Texturing |

|

Drying |

|

Preferred Fastener |

|

Typical Weight Per Linear Foot |

0.75 lb

|

Cutting Waste |

|