Perma-Chink Chinking

Details

Free Ground Shipping

We are offering free shipping for all sizes of this product purchased online and shipping to the Lower 48 United States. Offer does not apply to Alaska, Hawaii, and the US Territories. Free Shipping applies to this item only and not the entire order.

Perma-Chink Chinking is a flexible, textured chinking that seals the open gaps between logs to eliminate heat loss and air infiltration. Even though it looks and feels like traditional mortar, it's not. Perma-Chink Chinking is a pure acrylic that adheres to logs and stretches to maintain a tight seal by following log movement.

Application can be done by the homeowner or a professional contractor.

Features & Benefits:

• Eliminates Air and Water Infiltration.

• Remains Flexible to Allow for Log Movement.

• For Exterior and Interior.

• Suitable for all Climates.

Coverage Rate Chart:

• Coverage Chart refers to linear feet per 5 gallon pail of Perma-Chink.

• Perma-Chink should be applied 3/8" thick.

• 1 Pail = approximately (55) 11 oz. tubes.

• 1 Pail = approximately (20) 30 oz. tubes.

Color Chart:

Where to Use Perma-Chink:

• Interior and Exterior.

• On chink-style log homes.

• To replace old, crumbling mortar on older and historic log homes.

• To create a chinked look on a wood sided surface.

Application Methods:

• Chink Pump.

• Bulk-loading gun and follow plate.

• Ratchet caulking gun.

• Application bag.

How to Measure My Chinking Project:

• There are two dimensions that you need to know in order to determine how much product you will need: the width and the cumulative length (linear feet) of the gaps or joints that you want to seal.

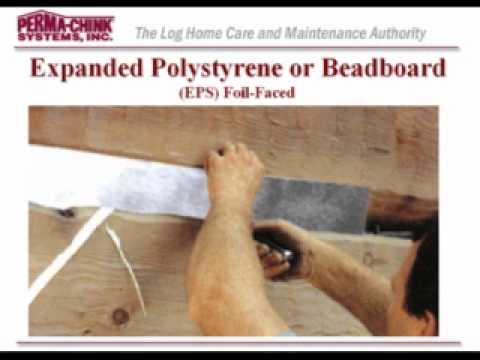

• Figuring the Width: If it is a chink joint on a squared log it is the average distance between upper and lower log surfaces. If it is round log chink joint you first have to insert a length of proper size Grip Strip and then measure the distance between the top and bottom logs about 3/8 of an inch in front of the surface of the Grip Strip

• Figuring the Cumulative Length (Linear Feet): It is best if you break it down to one wall at a time then add all of the walls together it becomes much simpler. Start by measuring the length of the wall with a tape measure. Then count the number of joints you need to seal. Usually it is the number of log courses minus one. When you multiply these two numbers together you have the linear feet of sealant required for that wall.

• Keep in mind that the depth is an average depth across the joint. We tend to think of the depth in the middle of the joint where it is actually the thinnest. If your estimations are generally short, check to see that you use average joint depth.

Colors:

• Beige 216, Black 227, Brown 223, Cedar 230, Light Gray 212, Medium Gray 224, Sandstone 215, Stone 211, Tan 219, White 207

More Information

|

Recommended Chinking Application Tools: Preparation Instructions: Application Information: When to Apply Perma-Chink: Can Perma-Chink be Applied In Hot Temperatures? Why is Backing Material Needed? What Types of Backing Material Should I Use When Applying Perma-Chink? Drying & Curing Information: Clean Up and Storage: Maintenance Information: How To Avoid and Correct Blistering: How to Repair Torn Perma-Chink: Perma-Chink How-To Guides For Perma-Chink Chinking: |

Reviews

Product Questions

Product Questions

-

I'm planning to use chinking on my logs. What kind of stain should I use with it?

These days, most chinking projects utilize water-based acrylic latex chinking products and the chinking is intended to contrast in color from the wall stain. If this is your case, we recommend using a water-based stain with a clear topcoat for your log walls. This is more for practical reasons than compatibility concerns. Even though most chinking products are water-based, compatibility will not be an issue for most coating type oil-based stains as they don't stay wet long enough to affect the chinking joint. However, most coating type oil-based stains utilize a colored topcoat. This means that when you need to do a maintenance coat several years down the road, the stain maker intends for you to just clean the wall and apply a clear topcoat over your existing stain base. This presents a problem as you will need to tape all of the chink joints to keep the stain from altering the color of your chinking. Some prominent stains in this category are the Sikkens Proluxe brand and Sashco's Transformation Log & Timber stain. By contrast, most water-based log stains utilize a clear topcoat. With this type you don't have to worry about taping the edges of your chinking joints to keep the stain away. Additionally, you can simply coat directly over the chinking without fear that it will alter its color. Lastly, we recommend against using deep penetrating oil stains in conjunction with acrylic latex chinking. Deep penetrating oil-based stains are formulated to stay wet at the log surface for an extended period of time to allow the stain to penetrate deep into the wood fibers. Consequently, this type does have a tendency to release acrylic latex chinking joints. Some prominent stains in this category are Outlast Q8 Log Oil and Woodguard Stain.

-

Can Perma-Chink be stained?

Yes, both water-based and oil-based stains are likely to adhere to Perma Chink Chinking.

-

I'm going to stain my house with Perma Chink Ultra-2 and need to know if I should caulk the house before staining. What is the correct procedure?

Yes, you should caulk before using Ultra-2 or Ultra-7 stain. For the least visible sealant lines, choose a sealant color that's a shade lighter than the stain you plan to use because it's easier to cover a lighter color sealant with a darker color stain than it is to hide a dark colored sealant with a light colored stain. If you want visible sealant lines, you may apply Energy Seal after you stain. If you do this, it is best to apply Lifeline Advance topcoat after the Energy Seal. This results in a more even appearance. Application to surfaces with freshly applied oil-based stain should be avoided.

-

I have an older house that was chinked with mortar many years ago. The problem I'm having is the mortar is cracking and falling out in places. Can I use Perma Chink to go over the mortar to seal these cracks?

Unfortunately no, since the existing mortar is cracking and falling out. It is advised that you remove all of the old mortar before applying Perma Chink, since you need a sound foundation for this compound. Weak and crumbling mortar will eventually cause your repair to fail.

-

I live in Arizona and I applied my chinking yesterday on one wall. I have noticed some small blisters on the south side of my house. Can you tell me what might be happening?

Perma Chink is sensitive to direct sunlight which can accelerate the "skinning over" of the sealant. This can cause the water contained in the Perma Chink to become trapped which can cause out-gassing, giving this "blistered" look. Always apply Perma Chink on the shady side of the house or very early before the sun becomes too hot. You want the Perma Chink to dry slowly but when it is applied in direct sunlight, it may give you this effect.